- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

空気圧搬送システムが失敗するのはなぜですか? inchiは、隠された問題と解決策を明らかにしています

2025-04-25

Unexpected Shutdowns? Hidden Issues in Pneumatic Conveying Systems

While YINCHI pneumatic conveying systems excel in efficiency, common failures like pipeline blockages and pressure drops often stem from overlooked design flaws or maintenance gaps. Key warning signs include:

- Frequent blockages due to incorrect airflow velocity or material adhesion

- Abnormal pressure fluctuations from undersized pipelines or filter clogs

- System overloads caused by poor power distribution or valve malfunctions

Core Principles: How YINCHI Pneumatic Conveying Systems Work

Pneumatic conveying systems transport materials using compressed air through sealed pipelines. YINCHI’s expertise covers three main methods:

- Positive Pressure: Ideal for long-distance, high-volume transfers (e.g., cement, minerals)

- Negative Pressure: Perfect for dust-free collection (e.g., pharmaceuticals, food)

- Hybrid Systems: Combine both for complex workflows

Critical Components:

- Air sources: High-stability compressors

- Material pumps: Ensure precise dense/dilute phase control

- Ceramic-lined pipes: Reduce wear by 60%

👉 Explore YINCHI’s Conveying Components

Case Study: Power Plant Saves $1M with YINCHI Upgrades

A coal-fired plant faced constant ash pipeline wear and shutdowns. YINCHI’s solution:

- Replaced high-speed dilute-phase systems with low-velocity dense-phase conveying

- Installed ceramic-composite pipes (3x lifespan)

- Integrated smart PLC controls for real-time adjustments

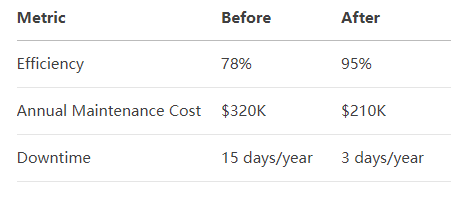

Results:

Strategies to Prevent Pneumatic Conveying Failures

Material-Centric Design

Analyze particle size, density, and moisture to select optimal YINCHI pneumatic conveying systems.

CFD Simulation

Prevent blockages by modeling airflow paths and minimizing bends.

Durable Material Selection

Use YINCHI’s carbon-silica pipes or stainless steel for corrosive materials.

Smart Monitoring

Deploy sensors to track pressure, temperature, and flow rates 24/7.

Proactive Maintenance

Schedule quarterly inspections via YINCHI’s Service Plans.

FAQ: Solving Pneumatic Conveying Challenges

Q: Can pneumatic systems fit compact facilities?

A: Yes. YINCHI pneumatic conveying systems optimize vertical or underground layouts.

Q: Are these systems energy-intensive?

A: YINCHI dense-phase systems cut energy use by 25% vs. traditional methods.

Q: How to choose between positive/negative pressure?

A: Consult YINCHI engineers for a free System Assessment.

Act Now to Eliminate Downtime

Don’t let conveying failures disrupt your workflow. YINCHI offers:

📞 Contact: +86-18853147775

📧 Email: sdycmachine@gmail.com

🌐 Explore Complete Product Range